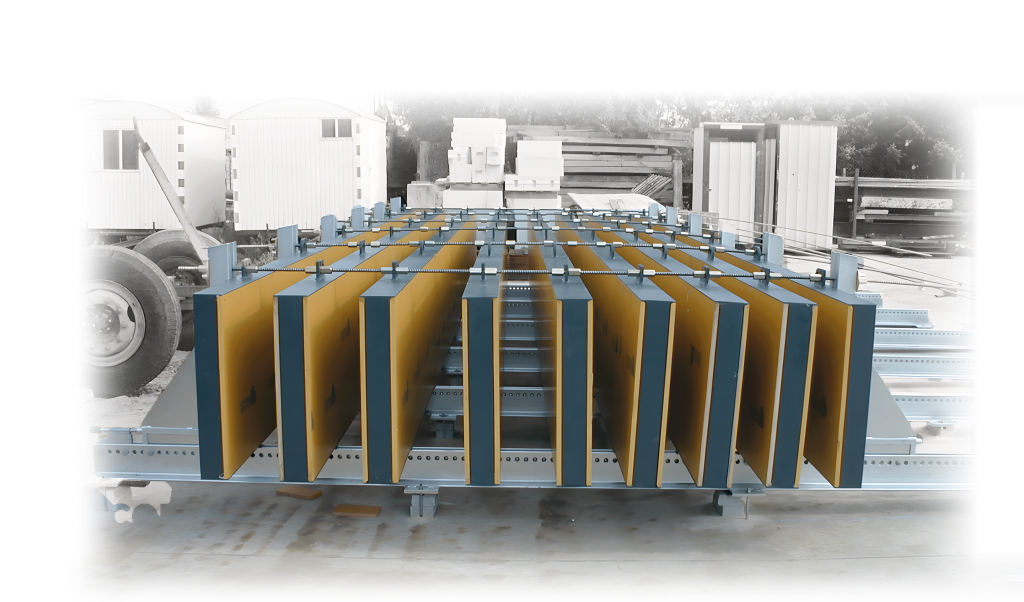

Simple & budget-friendly

PROPERTIES

The simplest and most budget-friendly battery formwork whi ch involves moving the panels with a crane. The length, height and number of panels per battery are theoretically unlimited.

As contact sheet, you can choose between 18 mm thick standard concrete plywood (with a 120 gr/m2 coating), tropical hardwood-based plywood (with a 450 gr/m2 coating) or a 6 mm thick steel plate.

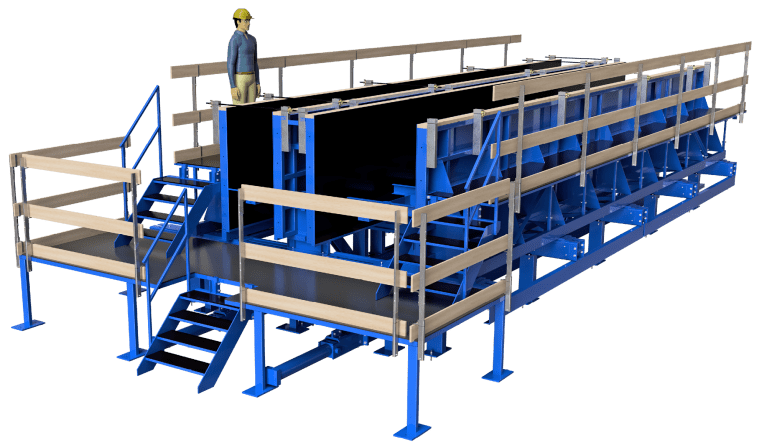

Efficient & versatile

Wheels are installed beneath the panels, running along the rails of the base. These panels can be manually moved without the need for a crane. Theoretically the length, height and number of panels per battery are unlimited. There are numerous options available as bottom support systems.

As a contact sheet, you can choose between 18 mm thick standard concrete plywood (with a 120 gr/m² coating), tropical hardwood-based plywood (with a 450 g/m² coating) or a 6 mm thick steel plate. Optional properties include nail wood, various types of fastening systems for the end panels, raised tie rod holders on top of the panels, etc.

PROPERTIES

Fully hydraulic system

Opening, closing and keeping the panels closed is done entirely hydraulically. This means that no manual actions are required to move or lock the panels. The bottom setup can also be adjusted hydraulically.

PROPERTIES

For smooth concrete surfaces on both sides

Cometal’s wall battery is designed to produce large prefabricated wall elements with smooth concrete surfaces on both sides of the concrete element. Thanks to the use of electric drive, the outer and intermediate partitions are easy to open and close, ensuring highly efficient operation.

PROPERTIES